How I helped a $1B+ supply chain company to build a 0 -> 1 product

The product supported a $1B supply chain business growing at a rate of 20% CAGR, within the largest retail business in Australia & New Zealand

.png)

Company Overview

Woolworths is the largest retail business in APAC and 19th largest globally, with 1400+ stores and 190,000 employees globally. I was part of Primary Connect - the supply chain arm of Woolworths Group including Supermarkets, BigW and B2B retail partners and is the largest retail supply chain network across Australia and New Zealand.

Product-led Growth Strategy

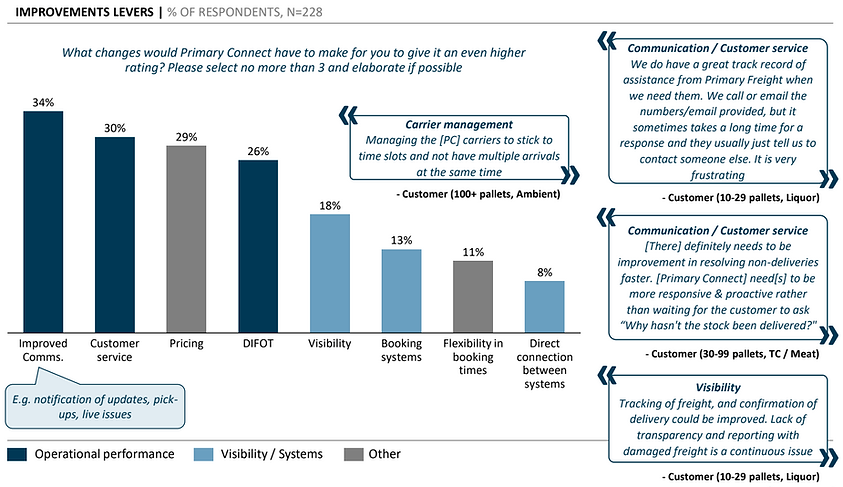

An external consultancy was engaged to determine issues for suppliers and carriers to deal with Primary Connect (Or Woolworths Supply Chain). Hence, a business decision was taken to make a significant investment to build technology-enabled next-gen supply chain.

Building

Vision

A digitally enabled, paperless supply chain that grows commercial opportunities in Domestic Transport and unlock new opportunities across International Supply Chain & Warehousing.

Objective

One Stop Shop for Partners: Offer a One Stop Shop for end to end logistics services enabling simplicity for our Supplier Partners and Teams across invoicing, order milestone visibility and order management

Program

Rollout a next generation ecosystem platform called "MyPrimaryConnect", focused on a seamless user experience, partner integration capability, full downstream systems integration, and scaled value added services capability.

Revenue Goal

Total investment of $48M in CAPEX and OPEX costs to protect existing business revenue from 1200 supplier partners and enable business growth to $1B by FY25

Top Capabilities

1. Suppliers to place orders to be delivered to our Distribution Centres (via MyPrimaryConnect app and integrations)

2. Carriers to accept 'tenders' and provide updates (via MyPrimaryConnect app and integrations)

3. End-to-end order visibility & milestone updates to key stakeholders (via MyPrimaryConnect app and email/text)

My Role

I was hired by Woolworths to start UX practice in supply chain. While Woolworths employs more than 100 designers and researchers, this discipline never existed in the Primary Connect supply chain business. My goal was to support a vertically integrated strategy and build a best-in-class product.

Establish Practice

Identified the project requirements, defined budgets, recruited and onboarded a team of 6 senior UX/UI designers and researchers

Strategy Refinement

Support leadership with customer voice through deep discovery research including surveys, interviews and idea validation

Product Delivery

Managed the design team across 8 engineering squads while balancing the needs of research and design for imminent vs. future roadmap items

Agile Transformation

Collaborated with leadership, engineering and product teams to define processes aimed towards efficiency and sustainability

Product Delivery Approach

DISCOVERY

HIGH-LEVEL DESIGN

DETAILED DESIGN + TESTING

EVALUATE OUTCOMES

-

Over 100 hours of research with 135+ Primary Connect customers, partners and teams.

-

Understanding of current state processes.

-

Articulation of user archetypes and design principles referring to research and best practice digital examples.

-

Service blueprint outlining the target state experience across all channels, systems and capabilities.

-

15+ customer journeys

-

100+ User flows to define the user experience in platform.

-

100+ features and 2500+ user stories broken down to prioritise into delivery.

-

20+ Co-design and concept testing sessions with customers, partners and teams to refine and iterate the experience.

-

Design of a modular, component based design system.

-

Detailed design and UI across all commodities and archetypes.

-

30+ User testing sessions with future users of the platform.

-

1.1M lines of code written

-

Product rolled out to 1200+ suppliers across 11 releases

-

Driver app rolled out to 20+ carriers

-

CSAT scores recorded at 80+ out of 100

Constraints

1. Technology Constraint

-

MyPrimaryConnect has an extremely complex technology ecosystem

-

The technology also needed to ensure it is fit for purpose and aligns with the Woolworths Group system landscape.

2. Business Constraint

-

Product and Development teams are two separate entities with their own priority roadmaps. Hence, alignment was difficult and security, compliance, project management resources led to additional costs

-

It was difficult for Business Development teams to completely articulate priorities.

My team had to work on a complex product in a complex industry, under the cost and processes constraints. As a manager, I brought several process improvements like new stakeholder engagement model, involving Development teams early, creating value canvases, running prioritisation exercises, etc. This ensured the roadblocks were cleared, risks were mitigated and delivery timelines were met, while keeping the team engaged and upholding high design and product standards.

Design Deliverables

Research Synthesis

Service Blueprints & Customer Journeys

Design System

UI Designs

Outcomes

Success

Support $1B+ business

The self-serving capabilities and ease of use enabled sales teams to win new and lost enterprise customers

+20 bps CSAT improvement

Increase Voice of Supplier (or CSAT) by 20 bps, with "User Experience" mentioned as the key driver

$1M+ cost saved

Reduced onboarding and training costs by $1M+ and decreased support calls led to reduction of 5+ FTEs

Brand Recognition

Product was recognised for its innovation across the 190,000+ employees company, and by partners and large customers